Shop Notes:

Now that the floor is in, I can grab my trusty bucket (an upside down seat) and start to heat and dig out the epoxy plugs on the cabin sides to tighten them up. There are 13 screws on each side. I got no less that 1/4 turn out of every screw and as much as an entire full turn out of some and, all but one tightened down. I had to remove one that was stripped and re-drill for a new screw.

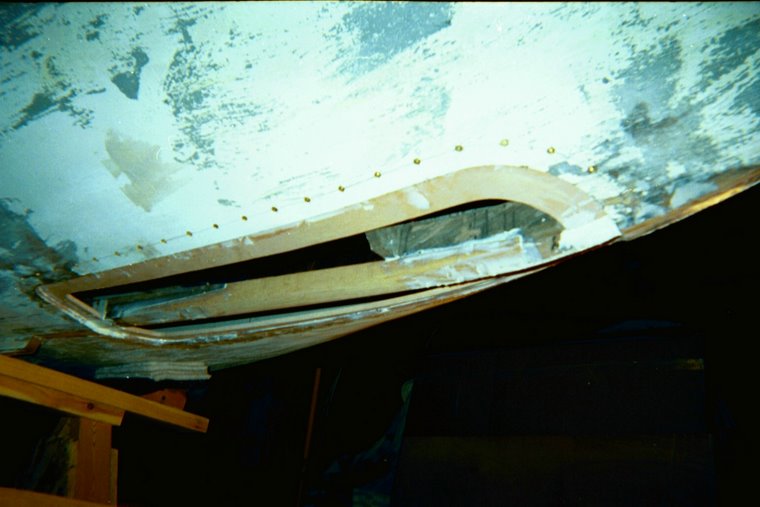

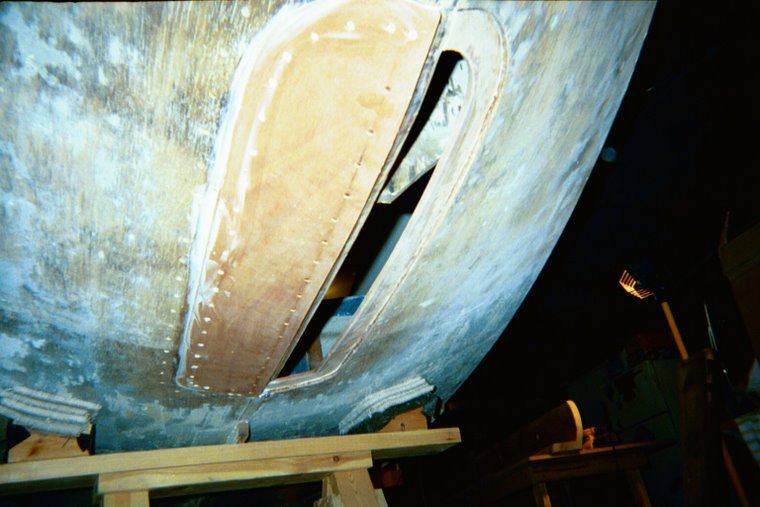

Later, I decided to take a look at the hatch. This thing is crooked and it's been bothering me for some time as to whether or not I should mess with it. I can't stand it... The wood around it (coaming ?) is rotted in places and it's just not square...

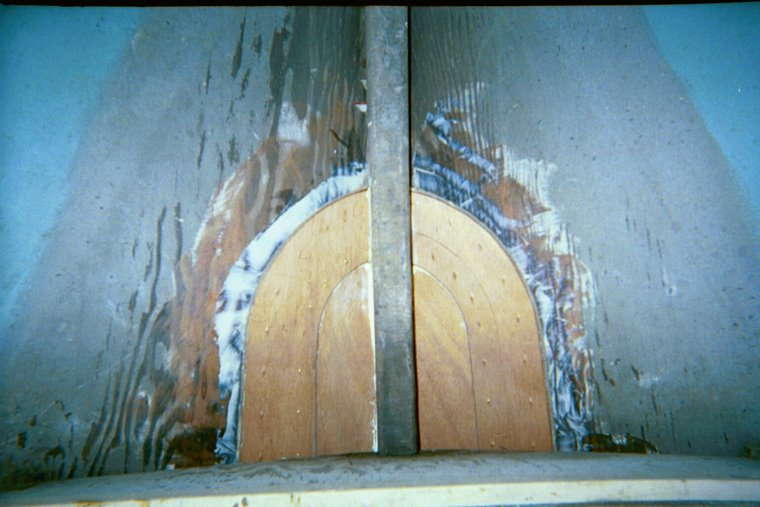

So, I started by removing all of the trim around the opening. I grab my square and straight edge and start studying this picture. I think this procedure requires a beer. Drink beer while looking at square crooked hole. Think..... think..... measure this.... measure that.... drink... think.... measure... you get the picture, right. Finally, I decide to start with the upper left (looking aft) corner of the hatch opening. I figure that I'll start with this corner and square everything else to it. So, with straight edge in hand, I begin to mark off excess wood that will need to be removed. I grab a rasp and my surform and start to shave off said wood. Remove a little wood here... a little more there... a slight cut from the jig saw in a couple of corners, a little more shaving and whalla ! SQUARE.

I can live with it now. Time to call it a night.

No comments:

Post a Comment