Today was a productive day. Despite it's beginnings, I actually accomplished more than I set out to do. We'll start with last night....

Today was a productive day. Despite it's beginnings, I actually accomplished more than I set out to do. We'll start with last night....

Last night I was tired. I transfered some measurements from the boat to my workpiece, with the intent of cutting that piece today. Even after measuring several times, I just couldn't get the numbers to add up right. I finally realized my mistake, corrected it, remeasured and was satisfied. Time to give up and close shop.

Today, I went to the shop with the intention of just grabbing that piece and starting to cut. I recently read on another fella's blog http://davesboat.blogspot.com (he's building his boat from scratch) that one should measure four or five times... then cut. This prompted a memory from high school where the shop teacher told our class to "Measure twice and cut once". Makes good sense. So I grabbed the tape measure and measured the distance across the cabin where the last beam would be installed and then checked that measurement against the workpiece and I'll be... It was wrong ! Not a great start but, at least I didn't cut it out wrong. As it turned out, after remeasuring and making the needed corrections, that particular beam turned out to be the best of the three. The angles were right. The length was right. The arch was good... all in all I was very impressed with my work. Someday, I just might advance from a Wood Butcher to an actual Woodworker, if I'm lucky.

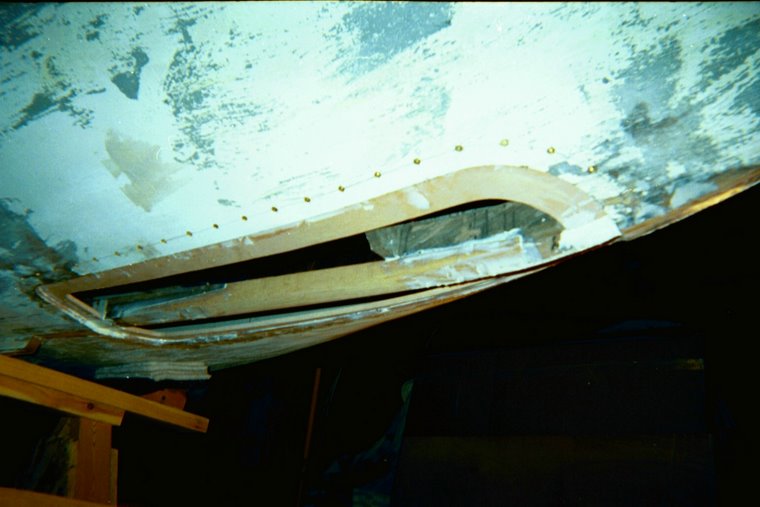

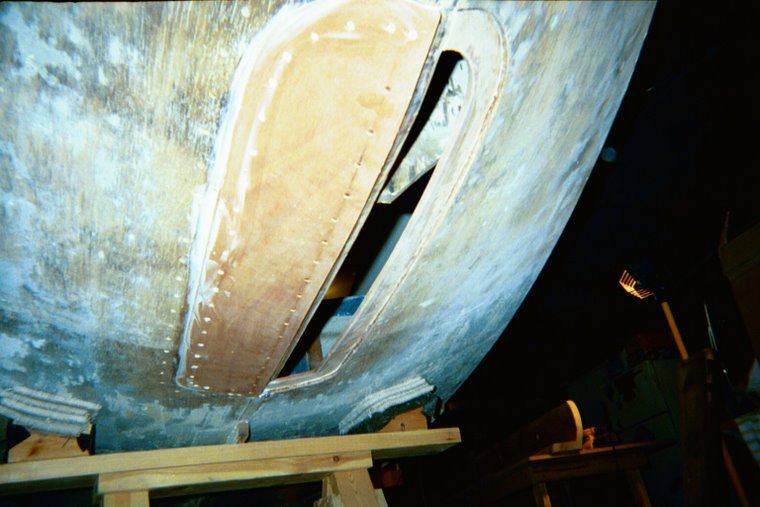

Anyway, I completed that beam, gloated a bit, and grabbed the bulkhead for another dry fit. Looks like it's going to need a bit of trimming in a couple of places. So, I haul that out of the boat and on to the bench for some marking and trimming. Another dry fit and all seems good. Wow, two for two...

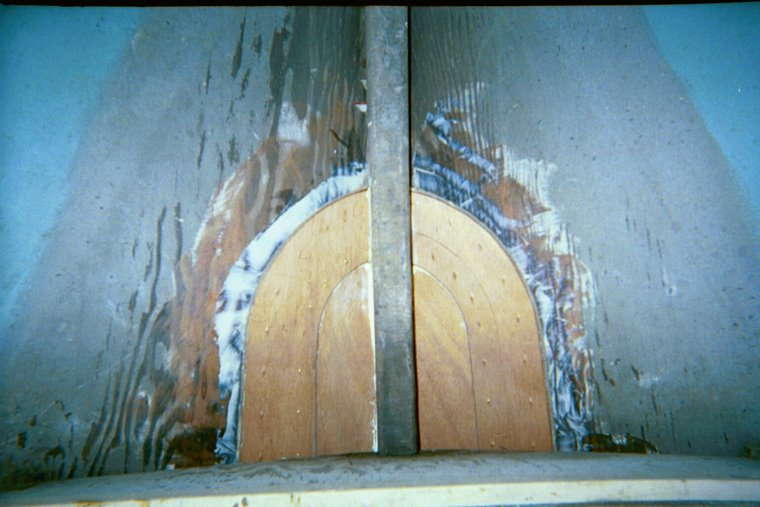

I then removed the bulkhead and set it aside. Now I have to mark the center of the last beam and the center of the front of the cabin for the installation of a cross beam (a beam that runs fore and aft across the top of the cabin beams). After marking the centers I clamped a piece of 1" x 3" Mahogony stock across the beams and lined it up with my marks on each end. I then marked each beam where the cross beam intersected, to cut notches for the cross beam to sit in.

Time to give some credit to the man (or woman) who built my boat. This person has a lot of my respect because he was able to build a boat... probably several, and I am only learning to repair one as yet. But... I wish that I had a whole bunch of what ever he was drinking when he did some of his work on this thing... I mean, screws drilled in within 1/16th" (or less) from the edge of the wood. The beams were all crooked (spaced 15" on one side and 17" on the other ?). The cross beam... again, crooked... not even close ! An inch and a half off center on one end (this is what prompted me to remove the roof in the first place... so I wouldn't find myself laying in the cabin some peaceful night on the lake, staring up and thinking to myself "why didn't I fix that").

Ok, enough complaining... :)

I removed all three beams, one at a time, and cut the notches as needed. Had to attach a piece of stock on the cabin's forward wall at the top (above the hatch) to have something to secure the cross beam to... this is where the original one was installed an inch and a half off center and the screws were set in literally on the edge of the board. There was no other way to secure the cross beam here using the same holes and not enough space to redrill new ones. I'll have to fill those holes, as well as all of the other 10,000 holes in this boat, some of which I have already filled. That's something that I have failed to mention anywhere else in this blog. Many of the holes that I've encountered I have filled by inserting a piece of dowel peg rolled in epoxy. I've filled a lot of holes this way, fills the hole and seals it from moisture too.

It has occured to me today, during contimplation, that the average boat builder starts with a pile of wood and a set of plans and begins to build his boat... from that pile of wood up (frames, hull, cabin....). As for me... I had a boat to begin with. Then, slowly but surely that boat keeps getting dismantled, right down to a bare hull and frames almost. And then I get to build it back up. But, I haven't got any plans. I always have been difficult :)

Ok... after cutting the notches and reinstalling the beams, I went to install the cross beam and realized that this thing is going to have to be bent, steamed and bent. If I just attach it on one end and force it down, attaching it to each beam as I go, it's going to force the first two beams down, out of shape, possibly even causing them to fracture. Sooooo, off to the house we go to fetch a book that I know will give me the information I'll need for this proceedure. Frame, Stem & Keel Repair found here >

http://www.amazon.com/Frame-Stem-Keel-Repair-Woodenboat/dp/0937822426 I have resourced this book many times and find it to be very informative.

I finished off the evening with setting up a jig to be used for bending my 1" x 3" for the roof and locating a suitable container to use as a cooker for my steam. Tomorrow I'll learn how to bend wood... with steam. See ya.............................