Shop Notes:

Not a whole lot going on in the shop yesterday. Bought a few pieces of Mahogany to start replacing the cabin beams. The original beams are 15/16" thick. The replacement beams will only be 3/4" thick but, they will be a bit wider to maintain their structural strength.

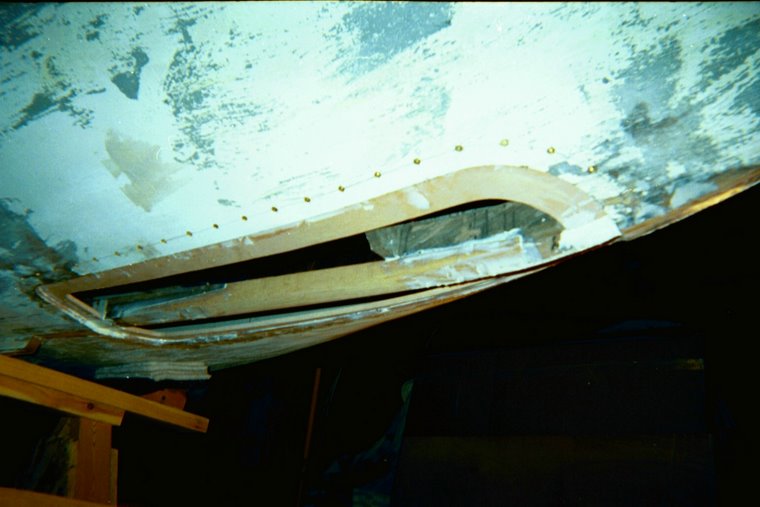

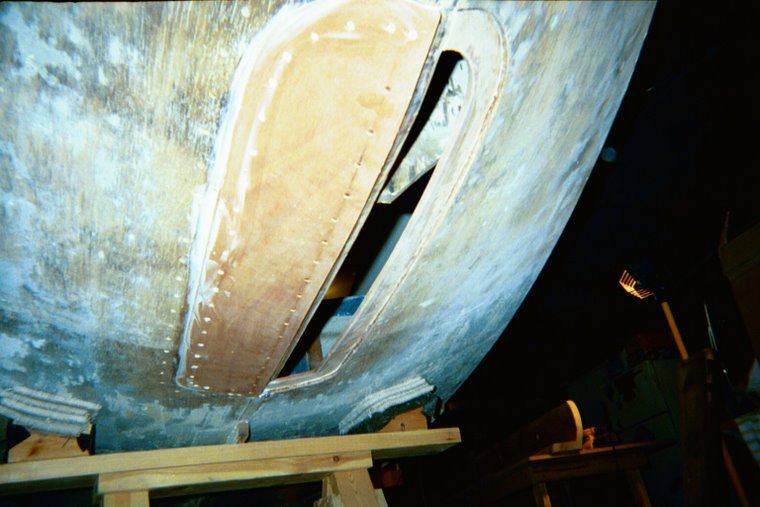

Removed one beam. Cleaned it up a bit, removing the crusties and what not, so as to use it as a pattern to duplicate it's arch on the new piece of wood. The original beams were fastened with only one screw on each side. Why, I don't know, since this did allow them to "spin" if it were not for the roof itself preventing them from doing so. Seems to me that 2 screws on each side is the smarter choice, as well as proper drilling and placement of the holes. So, that is what I did.

I made the one beam, positioned it, marked and drilled for 4 holes... 2 on each side and installed the first beam. Performed the ever so complicated technique of "eyeballing" it's position, relative to the top of the cabin, and grabbed the rasp. A little shaving across the fore side of the beam, to give it some slope towards the bow, and all looks good.

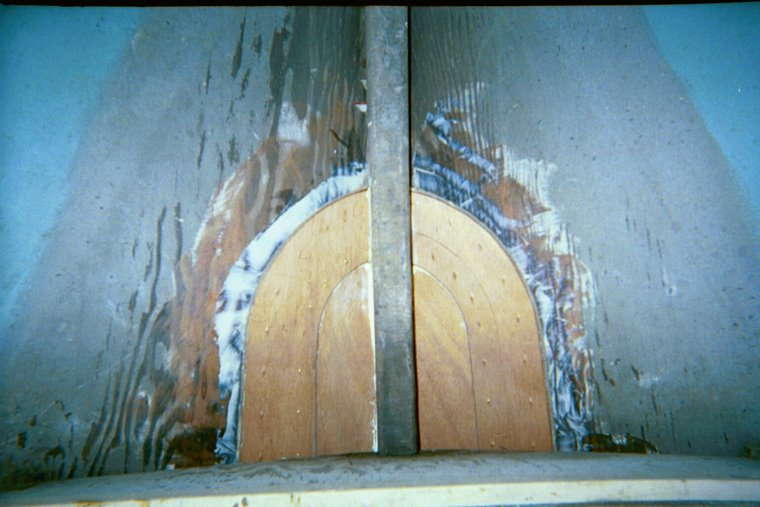

Today, I plan to remove the second beam and repeat the above proceedures. When this is done, I'll have to remove both beams to give them a good sanding and treat them with CPES before they are reinstalled permantly. After the first two beams are completed, I'll be able to remove the third and final beam.

I haven't decided how I want to do this one though. I'm considering fabricating and installing a full bulkhed from hull to hull and floor to roof with a thru-way into the cabin. The reasoning for this is to fully inclose the fuel cell's box (which will be in the cabin under the bed). Also, this would allow me to design a larger, stronger dash to accomidate the new teleflex steering system and guages previously purchased as well as a switch panel & fuse box for the electrical system... To be continued...

No comments:

Post a Comment